Basic corporate goals and commitment to total quality are set down in our quality policy.

1. Extract from the WINDAY quality policy

The quality of our products and services is an essential part of our corporate strategy, whose paramount aim is total customer satisfaction. Consistent application of a quality management system results in flawless products and a high level of user benefit from our components. Our quality management system always reflects the most stringent international standards.

2. Quality management system

The quality management system to IATF 16949:2016 is applied throughout the company and is used to implement the WINDAY quality policy.

The implications include:

- As a rule, product and process developments follow the rules of APQP1)

- Quality tools such as FMEA2), DoE3) and SPC4) minimize risks and ensure continuous improvements in conjunction with regular internal audits and QM reviews.

3. Certification

The WINDAY quality management system forms the basis for the company certification to ISO 9001:2015, ISO14001:2015 and IATS 16949:2016 that comprises the WINDAY plants and sales organization.

4. Quality programs

Project-oriented improvement programs pursuing the strategic objective of zero defects are set up and conducted by specialist teams.

5. Delivery quality

“Delivery quality” means compliance with the agreed data at the time of delivery.

6. Failure criteria

A component is defective if one of its features does not correspond to the specification of the datasheet or an agreed delivery specification.

7. Traceability

At all stages of production, components are identified by papers accompanying each batch. The completion of manufacturing and testing steps are confirmed and documented in SAP R/3. This ensures the traceability of a batch.

8. Final inspection/approval for shipment

Final inspection verifies the major properties of the end products batch by batch, usually by means of fully automated selection tests. Approval for shipment helps certify that products shipped comply with specifications.

It includes:

- Testing of principal parameters

- Identification check and visual assessment

- Examination of papers accompanying the batch

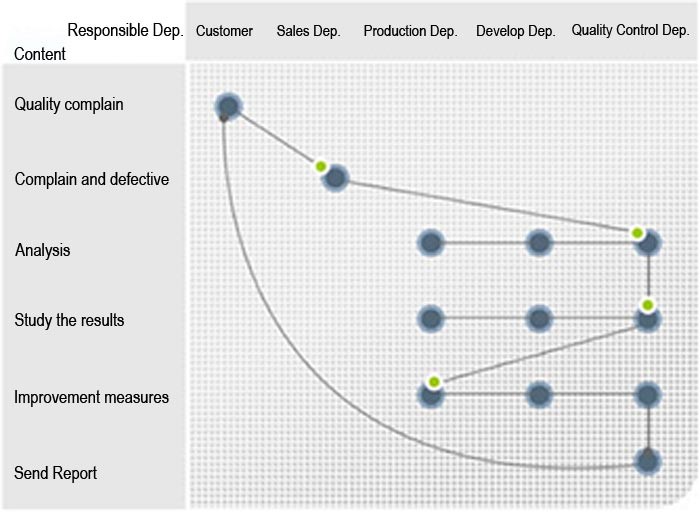

9. Manufacturing and quality assurance procedures flow chart

10. Quality process flow chart.